Preparing Fiddler's Green,

first for her 2013 adventure, sailing round England, Wales

and a bit of Scotland! We got over half way..

The preparation goes on, for the planned

second leg. South then west to the Scillies and thence north back to Scotland...

(and home on the back of an Artic!)

It was postponed, but now on for 2018. Mid June to mid August, anyone up for a cruise in company!????

(you have to scroll to the bottom of the page of course, for the latest bit!)

These pages will be updated on an almost daily, certainly on a weekly basis, as the boat is prepared and then the log itself, as often as possible as we set off on our big adventure.

The big plan....

John wants to sail his Eventide, ‘Fiddler’s Green’ round England, part of Scotland, touching in at Ireland and Wales, maybe the Isle of Man and the Scillies, on the way.

The basic idea is to leave the Blackwater, in May 2013 and head north, coastal sailing, up the east coast, stopping off at various ports of call, sailing by day with no leg longer than 50 miles if possible. The intention is to turn into the Moray Firth and head for Inverness and the Caledonian Canal. Crossing Scotland, via Loch Ness, then down the west coast of Scotland and England, going where the wind blows, so long as it blows gently!

Could be the trip of a lifetime, or fizzle out in Lowestoft if the weather is against me!

The trip to Cornwall 12 years back showed me that you have to be flexible. This time I have arranged to close my business for 3 months, passing all work onto the main Seagull dealer, but continuing to answer their technical queries as normal. I hope to be in touch by phone most, if not all the way. I am also looking into an easy way of writing up the log and publishing on the net all the time, by using modern technology, most things are possible. I’ve just got to get my head round it.

The study table is already covered in new charts, the boat is as fit as it will ever be, fully surveyed OK 2 years back and just needs the normal fitting out. Motor is good and will just have the normal oil and filter changes before launch. The sails have been checked by the sail maker, the rigging replaced 2 years ago and all checked OK. All gear OK, I hope I am fit for it!

This trip will not be tackled without a crew and I have already spoken to a few about this. You have to be prepared to join the ship wherever I might be. Flexibility will be the key. If anyone with sailing experience would like to sail part, (or all) of the trip with me, (or sail in company in your own boat) please get in touch.

John

P.S. now in 2018, planning to set off on the second leg, Mid June to Mid August approx.

John was awarded the Barry Sturrock Seamanship trophy in 2014, for the content of these pages.

(2018 and we are getting her ready to complete the circle. )

|

Over the coming months I will explain what we

are doing during the winter fit out and what gear we are renovating or

repairing, and what extras we have to buy to undertake the trip. As you probably are all aware I run a small business, a hobby gone mad, supplying parts for British Seagull Outboards. One of my first concerns was how to go off sailing and still help my customers. Here I have struck lucky, as I have an excellent relationship with the parent company, British Seagull and the owners Sheridan Marine. Indeed Jackie who runs Seagulls is the daughter of Pip Sporle the surveyor who helped me in the building of F.G.! Jackie has stepped in to take all the mails, and supply spares so long as I carry on answering all the technical enquires for her! No problem. |

|||

|

The Crew... |

|||

|

Skipper John

|

The next major issue was crew. I would

not attempt this alone. (I have serious issues with solo sailors! It is

impossible to comply with the look out provisions of the collision regs!).

Fortunately I have a number of stalwart friends who often sail with me, so

it has not taken long to fill the vacancies, but there is always room for a

third hand. At the moment the plan is to start with Phil as crew till end of May, then Brian the fund Manager steps in, mid June Keith the brother in law joins for a couple of weeks. 1st July my daughter, an accomplished sailor and RYA coastal skipper, practical, will join me for the duration of the trip, or at least till the 28th. Mid July, when the schools break up, the grandson, Brandon will come aboard!

|

||

|

Phil

|

Phil, long time friend and work colleague from our days on the London river, has sailed with me all over the place, Netherlands to Cornwall. Regular crew. He will be crew from day 1 till June. Sails his own 21ft Pandora in Norfolk. | ||

|

Brian

|

Brian, long time friend and sailing companion, also our fund Manager. Has sailed to the Netherlands with me. (This prove handy as he speaks Dutch). Has his own 30ft cat that looks just like an Eventide side on! Joins the ship 1st June. Wants to sail into Anstruther instead of being towed in! (another story!) | ||

|

Keith

|

Keith, long time friend and my brother in law! Ace tractor handler and tow master for F.G.'s trips on the road and oft my sailing companion. Has sailed to Holland and to and from the west country with me and back to the Blackwater. Many years of coastal cruising with me. He will be with me mid June for a couple of weeks. (at least). Says as a retired farmer he is skilled at 'Fettling'! (normally involves the use of a 4lb hammer!) | ||

|

Jenny

|

Jenny my daughter, an outdoors person, leads treks across the Sahara, travels the world guiding explorers and walkers. She has her Coastal Skipper theory and practical, Good crew. Will be with me from July till 28th. One day she will be F.G.'s Skipper! | ||

|

Brandon and Paul

|

Brandon the grandson, and his dad Paul are going to join me for the last leg along the south coast and back into the Thames Estuary. Brandon sails an Oppie, as well as plays with the 9ft dinghy in the picture, but has been forward lookout on many occasions on board! Paul is a novice sailor, but as he is a plumber, good man to have aboard! will keep the water where it belongs! | ||

|

I was hoping to be back by the end of July,

well a bit ambitious maybe, the trip will probably take till early to mid

August... got to be back for my birthday on the 12th so I can say I

did this when I was 65! Doubtless will be looking for more crew, so nearer the date....

|

|||

|

Preparing the boat and gear! |

|||

|

ready to go back in 2012 note shiny prop and wedges under the transom to prevent the stern digging un under power, works! |

Rigging, sails, motor and ground tackle and warps etc. Fiddlers Green was launched in August 1990 and after 20 years or more afloat has, in recent years had a few major jobs done. The rigging was replaced 2 years ago and 3 years ago the Beta 17 inboard had a very thorough overhaul. Fuel capacity 36 litres, in cans further 30. Rig and motor tip top. The sails are valeted every year and 2 years ago I replaced the mainsail, the genoa is in at the moment for small repair and washing. I carry main, genoa and boomed staysail, all on the spars, also spare yankee jib on wire luff to set flying and a cruising chute, in a snuffer, with large green fiddle on it! Also below is a storm jib with sheets ready attached and separate fairlead blocks on deck for it. (Never been used in anger!) The main has 3 sets of reefs and the genoa is on Plastimo roller reefing gear. All in top condition. All running rigging checked annually, washed and any problems rectified. Last year the main halyard and topping lift replaced, the year before the genoa sheets and staysail halyard. As they were 20 years old plus the annual washing and checking had paid dividends. Look after your kit and it will repay you. Fenders and mooring lines get the same treatment. (fenders are green of course!). The main bow anchor, is a 35lb Delta with 2 shackles, (55m) of 5/16 chain, marked every 5 metres with cable ties! Operated with a vertical spindle windlass, wound with a standard winch handle. The main anchor is stowed on the bowsprit, ready for instant use. Last season I replaced the heavy, stiff kedge warp, with a new 50m multiplait with chain attached. I also have a reel of 'Ankerlina' flat warp in the stern. 2 kedge anchors small Danforth and 20 lb Delta . The latter was the main anchor for a time and it's holding power is phenomenal, but it could not drop through kelp, so was changed for a much larger version.

|

||

|

echo sounder and log VHF speaker and rev counter |

Electronics and navigation gear aboard. We have VDO echo sounder and log, a matched pair, the log's head unit was replaced a year back and in good working order. In addition I now have a Stowe trailing log mounted on the stern rail, independent, with it's own internal battery. The engine has a rev counter. Very useful. at 2000 revs motor uses approx 2 litre per hour and attains 4 knots in calm water. At 3000 revs, 3 litres per hour and 5.5 to 6 knots. (Tank holds 36 litres.) (Tank replaced with larger capacity one after the first leg!) Navico tiller pilot. Main steering compass a Sestrel grid under the tiller and a hand bearing compass is carried. An MLR GPS is linked to a ToughBook laptop with AIS input and a SeaPro plotter program. If I can afford it I may get a second , small, independent, GPS plotter that I can see in the cockpit. VHF is old school, not DSC, but with a telephone hand set, good to be able to hear if it's noisy. 2 waterproof hand held radios are carried, one in the charger, the other in the panic bag. Skippers Binoculars, please no twiddling the knobs! Also another small pair carried for the forward lookout! Full navigation lights at deck level, steaming light on mast. (no mast head tricolour). Spare bulbs carried. Auto, dusk till dawn riding light, LED. Also day signals. Night lights below. Full set of Imray charts will be carried, Admiralty folios on board for normal cruising area already, plus pilot books, half are already purchased and being browsed. Normal half Admiralty size chart table with dividers rules etc.

|

||

|

Our life raft, serviced and up to date! |

Safety gear etc. A Seago 4 man life-raft is carried, (as well as an Avon dinghy), serviced and up to date. (after the first leg the old life-raft was sold and replaced with newer one..) The panic bag will have water, 3 survival suits, the hand held waterproof radio, a water proof camera, chocolate and an EPIRB. Topped up with other safety gear too, small pack flares. For the next leg we now have an additional 2 personal location beacons and an LED flare. There are conventional flares. Large container full! 1 set in date, others a year or two out. Anti collision white carried. Rechargeable search light, Maglite, head mounted torch. Again for the second leg the old type flares replaced with LED flares, longer durability and no danger of singeing eyebrows! 5 Fire extinguishers inc auto in engine box and fire blanket in galley. Firdell Radar reflector on mast. Emergency VHF antenna carried. Full first aid kit, to be updated. Air horn and mouth trumpet carried. Skipper and mates life jackets, with harnesses, plus 2 spare slim fits new and 3 older type lifejackets, all tested every year. (plus a couple of kids jackets...) Crew will probably bring their own. 2 spare adult harnesses. Webbing jackstay fitted on deck, ends being stitched this week. Large hook on U bolt in cockpit. 24" high guard rail wires, double, with stern rail and pulpit. A keel bolt is drawn every 4 or 5 years and this winter I will draw another, just to check... so far all have been like new.

|

||

|

Fridge battery monitor showing charge rate and condition |

Comfort. Galley has electric fridge with ice box, running from own 200amp batteries and 2 burner and grill cooker with oven with regulator. Heater in fore cabin, though hope we do not need that! 2 small size Calor bottles carried in gas tight, self draining locker. Paraffin cabin lamp (and also a spare paraffin riding light). Fuel carried in self draining locker. All internal lighting now converted to warm white LCD, uses very little electricity. Batteries, 3 banks, start, services and fridge, all separate, 400 amp hours, charged by 32w solar panel on spray hood and by X-Alt controller and X-Spilt, fully automatic. Batteries monitored by Nasa Battery monitors, picture on the left shows fridge battery bank charging at 22 amps! Water, 25 gallons in tanks with 3 gallons in cans for emergency. Fuel, 8 gallons (36 litres) in tank with further 6 gallons (30 litres) carried in cans. Water to galley filtered. Heads, a Lavac with holding tank, fitted with gauge. 5 berths, 2 in focsle, main saloon converts to double, (but will probably just be used as a single on the trip), and 1 in quarter berth, the skippers bunk if needed! Cabin carpeted! (Waterproof kitchen carpet!). This boat was built for comfort.! Bound to have missed something of the list, ask if you have a query!

|

||

|

Fitting out 2013. This part will contain details of the work undertaken and items acquired or serviced and the whole page will read chronologically, so you may have to scroll down to the bottom to read the latest.... |

|||

|

|

|||

|

massive 3/4 drive socket wrench with extra extension. You can just see the splintered wood on the pole, another job to sort! As it came out you can still see the old grease in the threads |

Wednesday January 9th 2013. Spend a few hours on board and lifted out the fridge batteries, all 200 amp hours of them, taken home for de-sulphating and charge. Broke out the heavy socket and 3/4 drive to remove a keel bolt. I took the first bolts out in the 2001/2 fit out, No's 4 and 7, they were fine. In 2005/6 fit out I removed another, no 1. Again bright and shiny. This time I removed No 5. At first I was going to admit defeat after straining for 5 minutes on the floor with both feet braced against the tommy bar. Then reason prevailed and I broke out the stainless mast lowering gear. One of the tubes was exactly the right diameter to act as an extension. Again with feet on the tube, I heaved, after a second or two it moved! However I managed to chew a little off the cabintop and table support pole where the spanner rubbed, so have to clean that up and re-varnish it. The bolt unwound slowly at first, so I squirted WD40 down it, eventually it began to move easier and I fitted the ratchet to the top and wound it out. It is screwed 4 inches down into the top of the cast iron keel! As you can see the bolt was bright and shiny so it was duly re-greased with waterproof grease and wound back in. I tightened it as much as I could, but will let it sit for a week and then have another go as the grease may prevent it going fully home. I am very happy the bolts are still good. Mild steel, galvanised and into cast iron! John.

|

||

|

|

|||

|

About half the charts I will need |

Wednesday January 16th 2013 Today I was back down the boat and got another 1/6th of a turn on that keel bolt. That was as much as I could tighten it without doing myself an injury! It is tight! Whilst I was aboard I removed the start battery, still showing 13v, but it will be put on a trickle charger till spring. I also measured up to see if I could fit another battery to beef up the service battery capacity. At the moment I have 100Ah and for this trip, although I suspect the motor will be working half the time and hopefully the 32w solar panel will get some sunshine, I figure a bit more battery would not go amiss. Sadly the space next to the services battery and just aft of it, was too small to fit anything of any decent size. Measuring up and using the start battery as a guide, I realised the best I could do was get another the same size as the start battery, 88Ah (90) and fit it under the step, where the start battery used to be, a year or two back till I opened up a void at the side of the engine under the bridge deck and made it into a battery and store compartment. So I am looking at batteries and so far have found the same battery as I already have on our EBay page for £15.00 less than I paid 2 years ago for the additional identical 88Ah battery for the fridge. So an order to go in shortly for a new battery, using our page. Last month it paid out £50 plus to us for the webmasters time! Whilst searching for charts, I have also looked for Tidal Atlas's. I like the Admiralty ones, used to using those for teaching. I was amazed to find so many for sale above the list price of £10.30! Not everything on the Bay is cheap, you have to keep your wits about you! I have my eye on one tidal atlas, and another chart at the moment, but have found that at Maldon's chandlery, Marinestore, they can beat everyone on the net on Imray charts and Tidal atlas's, so eventually I will go there to buy all the ones I cannot find cheaper! I am also saving for a new chart plotter, I am after a 7 inch screen, stand alone device that I can fit just inside the aft facing, opening, cabin window, so I can see it and use it from the cockpit. Whittled the list down to 3 now. The Lowrance Elite7M, or it's newer model the HDS7M, or the Standard Horizon 300i. Off to play with some at a chandlers shortly, already have an emulator for the Standard Horizon downloaded and working on my P.C., the wonders of modern electronics. Whilst on board today I double checked the fuel and oil filters I have and just need to get one or two as spares. Will get another Vee belt for the motor as well, so I have 2 spares aboard. Looking for a Jabsco water pump to sort and renovate as a spare too. Already have a Speedseal fitted, but will upgrade to the new run dry pump as well. Sadly found a bag of dry cell batteries that I had forgotten, in the bottom of a locker, and to my dismay one had leaked, so all the dozen or more batteries in the sealed poly bag were corroded and had to be tossed! Can't win them all! I will be working on the dinghy's Seagull outboard shortly, a job I can do in the warm, as it is minus 2 outside! John

|

||

|

|

|||

The new Speedseal life filters 'o' rings new pump and exhaust water injection bend |

Friday 18th January 2013 Just taken delivery of a load of Beta marine spares for the boat. I had been looking for a used Jabsco pump to renovate and take with me as a spare, but could not find one, and the new price was alarming, £500! How on earth can a pump be worth that!? Beta Marine came up trumps, they have replaced the Jabsco with a Johnson, and I have one for less than £100! Brand new! Well worth it. (So much easier to change a complete pump than to fiddle about trying to replace bearings and seals.) I have to modify the pump slightly, as I had to the Jabsco already fitted, as I have a different pulley system now on the Beta. It is a Beta mod for A section belts and to speed up the alternator to assist cooling. Beta supply an installation drawing and it will take 10 minutes to file off a small part of one of the supporting webs, to ensure the belt does not foul. Whilst I was on to Beta I got more spare fuel and oil filters, an air filter, another set of 'O' ring seals for the heat exchanger, 3 impellors and an exhaust fitting, the cast water injection part and all for half the price of a pump elsewhere! (why injection bend? well they only last 5 to 7 years so as the last one was fitted 4 years ago....) I also spoke to 'Speedseal' yesterday and have ordered a new 'Speedseal life' up grade cover for the Jabsco. It ensures longer impellor life and run dry capability, if the water inlet gets blocked by weed or a poly bag. Sadly though the present 'Speedseal' cover plate will not fit the other pump. I may work out which Speedseal life cover that Johnson will need. Probably not invest in one, as the Johnson is to be just a spare and I will get the Jabsco rebuilt if it fails, that is easy enough to do in a workshop and seals and bearings are cheap. Used our EBay page again last night and bought the 2013 Cruising almanac. Always liked the CA book , but last one 12 year old, so about time I had a new copy! Snow forecast and minus one outside, so chart correcting today! Boss has just told me I need to get the net curtains off for her to wash, OK, but not today! John

|

||

|

|

|||

|

CA Almanac some of the courtesy flags Y chart of Isle of Man

|

Tuesday 22nd January. The Cruising Almanac and a chart of the Isle of Man arrived yesterday. Also the Speedseal Life water pump cover, so I will be down to the boat shortly to fit engine parts and prepare for the engine oil change etc. First of the courtesy flags has arrived too.! Plus a new webbing strap to hold down an extra battery! The rather nice thing this page has produced is the interest and offers from members, I now have Tony with 'Iona' and Jackie of 'Cevamp' in Wales interested in escorting me, also Ron in Scotland with 'Gypsy' and Tony in 'Eric's Avocet' as escort round the Wash! Tony in Wales has sent me a couple of DVD's of views of the pilotage round his neck of the woods, Jack Sound, Pembrokeshire! scary stuff! Busy, busy, busy! But 2" of snow still on the ground here, so downloading corrections! Trying to buy a few charts on the Bay, (using our page of course!) but the seller is being odd, seems to have sold them outside the auction, wonder why he has a feed back of Zero and another account? Very odd. You have to be so careful. However I have found that Maldon's chandlery, 'Marine Store', beats every other seller in the UK on price, so if I do not get lucky buy half price, in date, charts, I will give my local shop the business! They are also the cheapest on Admiralty Tidal Atlas's too. Off to post Seagull parts, then home to correct another chart and scare myself silly looking at the warnings in the pilotage notes! John |

||

|

|

|||

|

This pic of john was taken at the annual meeting last weekend, john is holding 'Pusscat 3' one of the 2 kittens he brought along to the bar for the manager, Mike. Yes there are 'Pusscat' and 'Pusscat 2' as well, but the other kitten a real cutie, is called 'whiskers'! Apart from being trained mousers they are great fun in the bar, so long as there are no dogs about! |

Tuesday 29th January 2013. Today I lifted off the last of the main batteries, a heavy 110amp service battery, it was still showing 12.6v and powering all the lights etc, but is is now being charged with my special reconditioning charger and the 4 other batteries, already reconditioned, are all on trickle chargers. To keep the onboard lights working I have fitted a very small, 5 Ah sealed lead acid battery to the system with simple crocodile clips, this makes the lights work and working on board easier! I am still looking for a good position for another battery to add to the services bank... and may soon purchase that extra battery so I can actually offer it up into the available spaces. A safety strap to hold it down arrived in the post today. A couple of days back I dropped in at our local bearing and belts shop and purchased a couple of new Vee belts. There seemed to be a slight variation in size to what I already had as spares on board, so today I fitted one of the new ones to replace the slightly stretched belt on the motor. It was a real tight fit to get on. I will take the two other belts I had back into the shop tomorrow, for the lady to carefully measure them against the other new belt. If they are too long they may not be of much use! At £6.00 a belt the new ones were not cheap, but I am assured they are as strong as I can get in an 'A' section belt. 10 years or more ago I changed the flimsy 'Z' section belt drive and belts on the Beta to 'A' section and even though I have a smart charger on the Alternator, an X-alt, the belts last a full season. I was getting through 6 belts a year in the thinner 'Z; section. Totally unsuitable. I know my feedback to Beta Marine was partly responsible for them up-rating the belts on later motors. I also picked up another set of oil and fuel filters, so I now have 3 sets, one to fit, soon and two to stow on board, just in case... and I have found a suitable sized, sealed plastic box for them. I rummaged through my boat store today and sorted out some books. I carry on board Tidal stream Atlases for Dover Straight, The Thames Estuary and the Southern North Sea. I have just taken delivery of the Atlas for the North Western North Sea, so all the east of England and Scotland now covered. Looking for the rest... Sadly I realised that the Dover Straight chart I had carried was out of date, so there is another to add to my list to buy! Sorted out the lifejackets too, will bring those indoors to blow up and test and get the little CO2 cylinders weighed in the post office... With the temperatures up into double figures suddenly, nipping down to the boat is rather more appealing than of late so ticking jobs off the list. We have a crew meeting here this Sunday and all but young Brandon will be able to attend, Lots to explain and lots of questions to answer I am sure. From sleeping bags to life rafts and torches, suggested harbours and possible timings.... Thanks to Tom Greenwood for the 3 DVDs of the Welsh coast, some interesting places to visit and some rocks to try and avoid! Back to the day job.... John

|

||

|

|

|||

|

Meet 'Salty' The new ship's mascot for the trip. Complete with lifejacket! (designed by me over 30 years ago and used by all manufactures since, with my blessing!) |

Tuesday 5th February.

The crew all met here at the weekend!

Pleased to say all could come, my daughter Jenny from Devon and young

Brandon and his dad, Paul who are now geared up to join F.G. on 28th July... Not sure some were impressed with the 2 fold up bikes though! Too much like hard work maybe! Lifejacket rules and harness rules discussed, lifejackets all the time and harnesses clipped on when on on deck, except in flat calm, and at all times if alone in the cockpit! Finished off the get together with an Indian takeaway. A good afternoon and evening. Some of the crew will need new Fiddler's Green crew jumpers and shirts, so measurements awaited so I can order them. I have to scan the GPS instructions to send out to all, just in case they have to use it! All bar Brandon and Paul have VHF tickets and first aid. (though some a little out of date!). All in all think we have it all sorted, just need the boat back in the water and an order in for 3 months of decent weather. Took daughter back to the station for her trip back to Devon and on our return the new, extra 90Ahr battery was waiting for us! Finished watching the DVDs that Tom sent to me today and put them back in the post, some spectacular scenery and some scary tide races! Feel we are getting there, things are dropping into place. lots yet to do, but we are on the way John

|

||

|

|

|||

|

Saturday 9th February. I tested my EPIRB during the week and the battery failed the test, so removed it, it was dead as a dodo! Just 2v in a 9v lithium cell. Sadly though, to get the battery out the base cover split... with little hope I tried phoning the telephone number, to find it was unobtainable. I then worked out that I have bought the device a 'SeaMarshall PLB' in 2000, so it was 13 years old. the seals and arming protector had perished too. I was thinking time to spend £200 on a new one.... I tried the internet. Yes the company was in business. I phoned. I managed to obtain a new base cover, the seal for it and the large rubber band that stops you from activating it by accident, all for less than £20.00. A new Lithium cell for £6.00 using the EOG EBay page and it is all back together and tested OK! A result! I circulated a mail to the crew with the instructions for the MLR GPS, but have to be honest and say that unless you are standing in front of the GPS the crib sheets did not seem to make a lot of sense! I am waiting for sizes to come in so I can get some crew sweats and polos printed up, I have primed my printer friend that I have an order on the way, get those sizes in crew! I have sorted out a launching date with Keith and Phil, my normal helpers, week starting 21st April, so that should give 3 weeks afloat to get all the kit on board and tested! Will be servicing the Seagull tomorrow with any luck. The main drive shaft casing tube is going to be replaced, the old one a nasty plastic coated device, has rusted badly. I have been saving a good casing tube for just this day! Heard from Tim of 'Wedjit' yesterday and he has, as promised, removed the folding Ali mast steps from his boat and is parcelling them up to send to me. I will be fixing them to the ali mast. These could be a great asset, for spotting the coral heads off.... hey ho we can wish! All for now, antifoul on order! Jobs to do!!! John |

|||

|

|

|||

|

Sunday 10th February 2013. Spent a couple of hours servicing my Seagull today. It normally lives, chained up, on the sternrail under a cover. It has been on the back for at least 16 years and is 23 years old, one of the last they made. Over the years it has been used in creeks and canals, in The Netherlands and anywhere Fiddler's Green went. Being one of the latest ones she has a water injected silenced exhaust, that I have updated with the fitting of a small water delivery tube, it all works well. Sadly rust had eventually broken through the horrid plastic coating on the drive shaft casing tube. Years go all seagulls had chrome tubes and they did rust, the black plastic coatings looked OK for longer, but the rust was there, just under the plastic and out of sight! Knowing this I had put aside a chrome drive shaft casing tube. Today I went to fit it, Opps, it was the wrong tube! I had squirreled it away for nothing! Fortunately in my stock of old and obsolete new parts I had the correct tube in a long shaft version, 2 minutes with the hacksaw and I was in business. 2 hours later the Seagull was fully serviced, gear oil OK and all parts greased and protected plug checked etc. I will run it up in the test tank when the ice and snow goes! Another job ticked off the list. John |

|||

|

|

|||

|

Sunday 10th February, 1830hrs. Just won an EBay auction, using our page of course! Now we have the backup auto pilot the crew were asking for. A later version of the old Navico and the great thing is it mounts on the same pivot and clips onto the same tiller pin as the old one! Another tick on the list! John |

|||

|

|

|||

|

Saturday 16th February. I should have stuck to my self made rules for using EBay. Never buy any used electrical or mechanical items. The seller had specified 'dry and salt free'. Well part of that was correct! On opening the parcel water droplets were found inside the inner layer of packing. I started to have misgivings. In some trepidation I readied it for connection to 12v. I removed the plug on the lead, to find the wires were not at all fastened, just laying in their terminals.. Plug fitted by numpty! I attached 12v to the auto pilot and turned it on. To my surprise, it worked. However when I stood it on end, push rod down, a couple of dozen drops of (fresh) water drained out. The seal had plainly gone, as there was far too much lateral play in it. OK at least it worked. The seller had a 'no returns' policy, which when you see that it should ring bells, but as it was described as 'dry', and working I was reasonably confident. After haggling with the seller and speaking to Mansbrite Marine I eventually, begrudgingly got £35.00 refunded, or at least the process of an e-cheque started. I ran it into Mansbrite yesterday, they will investigate and if nothing else amiss will replace the seals and grease it. Will cost me as much as it cost to buy again! (Still cheaper than a new one, but would that have been a better bet?) Hopefully I will have it as a spare on board. I have checked and the end fittings do fit my existing Navico fittings on the tiller etc... Whilst I was down the boat I offered up a folding mast step, one of a box full sent to me by Tim of 'Wedjit'. Now got to measure the spacing and fit them. Off to boat with Brandon now, so he can have a look about.. john |

|||

|

|

|||

|

Tuesday 19th February 2013. Have not heard about my Tiller Pilot as yet..... but I have used our EBay page again and bought a Dri-plug to fit it so I can connect it to the existing deck socket. I have been using Dri-plugs for 20 years and they are excellent. A little smear of silicone grease, (or Vaseline) and the terminal connections have stayed clean. I have finished servicing the 4 main lifejackets I carry, 2 are brand new, still had the labels on them, but have not been checked for 3 years and 2 are 20 years old and look like new. To service them it is so easy. Gives great peace of mind too!. Remove the CO2 bottle and check the weight, Chetan in the post office weighs them for me, 138grams, weight is stamped on metal bottle. The activating cartridge removed to check it is still intact. (The paper trigger has not got damp). Check the mechanism works, then replace the clip that secures the operating arm. The jacket is then inflated by mouth and left for at least an hour, I leave for 6 to 24 hours, they must not appreciably deflate. Mine were rock hard still after 6 hours and just slightly softer 24hours later! Then the straps are checked for abrasion and carefully re packed. All have harness attachments. Job done! I have figured out how fit the mast steps. I have to mix up a paste of Epoxy with Ali powder, as a gasket between the back of the step and the mast, to accommodate the curve of the mast. The Ali past will make the Epoxy UV proof and look just like the step and mast colour. I will gently clean the steps to ensure they will 'glue'. I have sorted some large monel rivets. Still got the large rivet gun I used to build the mast. I am still occasionally using the EBay page to search for the outstanding charts, twelve of them! However the local chandlers sells them for £15.50 new, so there is no way I am going to pay the extortionate prices asked by some, I have seen £25.00 regularly and even over £30?!! I am assuming that these sellers are working on the assumption that there are Numpties out there who believe anything on the Bay must be cheap. Buyer beware! The other trick I have found is the 'New and unused', but they do not give the date of publication.. when pressed they are virtually all out of date so far that no corrections available. Simple to check, in my case Imray charts, go to their site and you will get the latest corrections listed with the date of the chart. No corrections for older charts so they are worthless! The sun is out again today and the frost melting fast, so probably a trip to the boat again later! John

|

|||

|

|

|||

|

Friday 22nd February. The Dri-plug and socket have arrived, new, in a vintage cardboard packet, just as the seller indicated, some old stock. A bag full of 1/4 monel rivets to fix the mast steps also dropped through the letter box yesterday. These are far stronger than plain Ali and corrosion resistant.. All purchased using the EBay page. A nice surprise this week, Andrew, my local doctor, who is also a sailing friend, popped round and left a present for me, a Saltire! (Scottish flag of St. Andrew!) He and his wife are Scots and we have an invite to call them up as we leave the Crinan Canal and they will meet us and cruise with us through the Islands of the Clyde. Having sailed locally here for a few years they have now bought a large Moody and keep her in Scotland. He also presented me with a publication called 'Welcome anchorages', published by the Clyde Cruising club and as it hints at, has details of friendly mooring places, many free if you use the hotel or other amenities nearby. Nice touch. I have contacted the Editor and have a 2013 edition being sent! I am gently cleaning off the traces of varnish on the Ali mast steps and as soon as the snow stops and it warms up a bit, will be down to the boat to mark up the mast and calculate where they will fit. As I type the snow flakes have got to half crown size and the horizon has gone. So much for flurries! I have short listed the company to buy the new GPS plotter from, (sadly not on EBay, so cannot use our page) and will be saving pennies hard so I can get hold of it early and play with it before we set off. Setting off. The date is set for 19th May, a Sunday, the tide serves at 0700, so we will go down the day before to get all stowed and other crew will maybe come down for a meal with us in the Marina bar that Saturday night, and stow some bits aboard, sleeping bags and the like. We have worked out we can stow the few extra on board, laid under bunks. Awaiting just one crews measurements till I can get the new sweatshirts etc. made, but he is away on holiday at the moment. Enough for now, John P.S. 1800hrs, just found and bought another 10 charts, cheaper than full price and all latest publications, an EBay seller I have used before just put a batch on. So now I have all I need bar 2 and one of those is the Suffolk and Norfolk coast I will be needing on day 2, but is available locally cheap enough. The other is a west country chart. I have also got a couple of bonus charts, Poole harbour and south east coast of Ireland, just in case! John

|

|||

Book from Andrew! |

Tuesday 26th February. Cold and grey outside but sunshine dropped into the letterbox in the form of a new up to date copy of the Scottish guide to moorings, 'Welcome anchorages'. I also have found another chart, the West Country one outstanding, a 2007 edition, but I have all the corrections for it and the 2012 one has few corrections as yet, that I will add.

|

||

Spare Autopilot, now repaired!! |

I have also heard from Mansbrite Marine

engineers that they have opened up the Navico Tiller Pilot and discovered

someone had tried to seal it with silicone! So the guy lied through his

teeth! Good news is the electronics were unaffected and sealed in

plastic. The unit works fine, but both the push rod seal and the case

seal are shot and have to be replaced. Final cost in excess of £100,

unit cost, with discount from seller, £95.00. OK still cheaper

than the £350 of a new one, but would I go that route again, no.

Needless to say I have left negative feedback, these bods should not lie when

selling.

|

||

Imray Chart |

Hope to get the last of the charts through the

letterbox shortly, have just 1 chart to acquire now and several tidal atlas's.

Will buy these in Maldon. They also sell Belfield's Tide CD for 2013

cheaper than anyone else.

I have decided to buy a new chart plotter program and charts from visit my harbour. At £30 it seems to be a very good deal, all the up to date charts of the whole of the UK and a copy of SeaClear plotting program. I have heard from John Stevens who has bought this that it works well on his laptop. Stopped to meet the postie, 9 of the charts have arrived already! All new and 20% off the full price with free post! Now off to download the latest updates to slip in each chart! More corrections to do. John

|

||

Epirb |

Thursday 28th February 2013. I have decided to update the EPIRB I have with the addition of a modern one. Found that one of my local Chandlers in Maldon had a deal on these Fast Find GPS units, so have splashed out. This unit can clip on my lifejacket and when activated will automatically send out a signal to overhead satellites, alerting Falmouth Coastguard that the boat registered to the device is in trouble and giving precise location. It will then also transmit the same homing signal the other EPIRB sends out, enabling lifeboats and helicopters to find you. With the other one though you have to alert the authorities by other means first or they will not be looking. Belts and braces! Hope to never need them, but a reassurance to the crew, and me! |

||

Auto lifejacket light, fitted to all 4 main jackets |

I have also decided to up rate the 2 lifejacket lights I have, with these, and have bought 4 to fit to the 4 main lifejackets. They are automatic and activated by immersion or switch. Batteries dated 2018! | ||

|

Another Imray chart arrived in the post today,

for the west country. I have already downloaded the corrections for it.

There is just one more in the post somewhere, for the Isle of Wight. For

some reason it has not arrived. The other 9 from the same seller arrived 2

days back. I have been enquiring everywhere about the last chart I have to buy, Imray C28, the Suffolk chart that I will be switching to on day 2! I had been unable to find a sensibly priced, in date chart for some time. Today a 2010 dated version came onto the EBay page. However a quick double check on Imray's corrections page tells me there is now a new edition, in January 2013, so all the older corrections for the 2010 charts have now been removed from the web. I asked the seller to reconsider the price as he was advertising it as the 'latest' edition and it was not. He still insists it is the latest, so I have again told him it is not and I would only offer half price, which is fair for an out of date chart. We will see if he replies. Suspect I will end up in the Maldon chandlers paying £0.50p more than he is asking, and buy the very latest. Will save me from doing the 2 pages of corrections I had downloaded and saved for the 2010 version, just before they removed them from the Imray site! Got to think ahead! I have also today ordered all the crews green sweatshirts etc. Got to have the crew looking smart! Jenny wants one with 'single and available' on the back! Am I going to have a problem with her on this trip!? John

|

|||

|

Program and charts for laptop as extra backup.

|

Thursday 7th March 2013. Still too cold and damp for real outside work so still gathering bits. The new lifejacket lights arrived, and today I picked up the new 'spare' Tiller Pilot from Mansbrite. They allowed the insides to dry thoroughly then fitted all new seals and greased it, now all fixed, but cost £114 to get it put right, overall cost £200 plus. Still cheaper than a new one, but of course no warranty! Fitted the new, 'old stock' DriPlug to it this evening. Bought another Admiralty Tidal Atlas from EBay, at a realistic price, still cannot find the last chart I need, Imray C28 for the Suffolk coast, so have resigned myself to buying that in Maldon. There is a brand new edition out and this will be the chart I will be switching to on the second day of the trip. Have continued to amend the charts I have, long job, but interesting to lay all the charts out and scan over them at the same time. Bought the complete chart plotter package for use on boat's laptop, charts for the whole UK and a copy of the chart plotter program 'SeaClear'. Actually the program was free. The lot for less than £32.00! One snag they have discovered, Avast!, the virus checker program, does not like SeaClear, so you have to go through a long procedure to exclude it from any virus checks. Pain but sure it will be OK.... www.visitmyharbour.co.uk if you are interested. Still cleaning ali mast steps prior to measuring and fitting.... Still lots to do... John |

||

Tidal Atlas |

Saturday 16th March 2013. Whilst keeping out of the cold and trying to shake off this nasty little bug the postman delivered this. New Tidal Atlas for the Whole of the Irish Sea. EBay purchase, including delivery still just cheaper than local cut price Chandlery! |

||

Tidal Atlas |

A day later another Atlas, from the EBay page,

this time not new, but exceedingly cheap, a well thumbed edition.

I can see from the pencil dates and times on the pages that it has been used

by someone who had the knowledge to interpret the pages... (Takes a bit

of a knack to use these correctly!)

|

||

|

Amazingly I still have not found a copy of the

Imray C28, this, being just a month into print, will have to come from the

Maldon chandlery and will still be half the price some sharks are asking for

older editions! If I feel better and the temperature goes up a tad, I will spend some time on the boat dry fitting the mast steps. As I intend to pace a small fillet of ali rich Epoxy under each step fitting, I need the temperature up to 10 degrees for the epoxy... but if all drilled and prepared will only take moments with the rivet gun after that. Had a hiccup with the McMurdo Fast find, the promised deal has not come off, the local chandlery is still trying to lay hands on one.. we will see. Have not chosen where to buy the last bit of kit from yet, the stand alone chart plotter to fit in the cockpit to cabin window. Know which one I am after, but now waiting on pennies. Then I will chose, it is between a firm in Cornwall or one on the Bay from Essex, though they are asking more... shame would be nice to bump up the EBay payment to the Webmaster.... All for now, off to throw logs on the fire! John |

|||

Epirb |

Thursday 21st March 2013.

After a lot of phone calls back and forth I have found that the local chandlery, 'One Stop', could not actually lay their hands on one of these 'Fast Find GPS' units. Ringing round today I found that unless I found a chandlery with one in stock the next batch were not due out till early or maybe mid June! not a lot of use to me! So having cancelled the local one I started ringing round. All said the same, 'yes it is advertised on their site, and no they have not got any!'. Until that is I called the 'Marinesuperstore' who not only had one they had three and one had my name on it! Bonus was the price was cheaper too! Will be in my hot sticky mit tomorrow! Then it has to be registered to the boat and me, so if ever activated, they will know what boat and who the owner is! Had a call from Devon today too, the pennies I loaned my daughter will be repaid shortly. Her house sale has come through... Thanks Eccles, so that is the Chart plotter almost accounted for! Yesterday had all the mast steps sorted and cleaned up. All in the van waiting to be taken to mast. As the weather is still so cold, cannot fit yet, need it above 10 degrees for the epoxy to set! Will be bringing that indoors to warm up shortly! Got to get warm soon... John |

||

Epirb |

Friday 22nd March. The EPIRB arrived today, tested OK and registration form filled in and ready to post. The weather has not been as clever, 3 above freezing and snow forecast... John |

||

|

Monday 25th March. 1 month to launch date and nothing done on board! The temperature outside is 0.1 degree C!! Snow laid all round, not much of it, we only got half an inch, but it is not melting and does not look like it will for the next few days! The only job I have been beavering away at is the correction of all the charts. Most of the 28 odd charts I have need correcting, most have 2 pages of A4 full of corrections and it takes me an hour some have 4 pages!!. The good thing is it also introduces me to the parts of the UK that I am not familiar with. I have amended all from The Blackwater north to Scotland, and west through the Scottish Islands.. some real scary bits there and I am now working my way down both sides (and the middle, Isle of Man.) of the Irish Sea. Some really interesting places to ponder over. I had no idea of the number of oil and gas fields all round us till I saw them all on the charts now they are also interspaced with Wind Farms, loads of them seemingly in the middle of no where! At least they are all lit! Surprising the number of small harbours having marinas built in them too. Passage planning on a grand scale! I wondered whilst I was doing the corrections, how many know how to do this? It would seem logical to work down the list of corrections from the top.. No, if you go that way you will end up adding work! To do it cleverly you start at the end and work backwards. Many times I have saved several amendments this way, buoys introduced and later removed etc.. I suppose I was lucky to learn all this at work... who tell skippers and navigators these wrinkles today? The nasty bug I got 2 weeks back is slowly letting go, but it is so cold outside I am loathe to risk it getting on my chest, so will carry on with the charts for now! Hope you are keeping warm too! John |

|||

Lowrance HDS7m chart plotter |

Thursday 28th March 2013. At last I have saved up the pennies to splash out on the last major bit of kit for the boat, the second, stand alone GPs plotter. This is to hoped to be mounted in the cabin window facing into the cockpit, the window slides open so I hope to be able to have the window open to work the controls and for the screen, to be seen from the helm. Better than popping up and down like a gofer to see the screen on the laptop in the quarter bunk! The Laptop will have another plotter program added soon, so there should be 2 programs to chose from on it and up to date charts too. These programs will have the AIS working on them. So I will still be using it if only for the AIS. Having corrected so many charts and now seeing how many navigational aids are being fitted with AIS it will now prove doubly useful. Speaking of charts, I have been working my way through the corrections and was 2/3rds there when I discovered that the supposedly indelible pen could rub off! Imray charts are coated with a waterproof layer and the pen does not appear to be permanent... Rats. so back to the pens I used to use Staedtler permanent ink pens. I have just ordered a set using our EBay page. (My old ones dried out years ago). With snow still on the ground here, and no let up in sight, fitting out time is telescoping fast! John |

||

Clever camera mount

Video camera and mount |

Wednesday 3rd April 2013. Its so darn cold. The icy wind is giving a wind chill reading of minus 11C now! I have heard that it is due to warm up by the weekend, but still not into double figures! So I spent Easter, (coldest for how many years?), re correcting the charts, have just 4 left to correct now! Better in the warm than in the snow! Will be down boat refitting batteries and servicing the engine at the weekend I hope, have a workday Tuesday or Wednesday, hope to get the mast steps on and wash all down ready to varnish (Sikkens satin stain!). Then it is polishing the hull and the prop and antifouling! Today the new toy arrived, the chart plotter. Impressive! I now see I can add a radar to it too, if I had the pennies! Radar has moved on a lot since I played with them! Now the radome is safe, the radio output 1/1000th of a mobile phone! New technology! So clever. Talking of new technology, I have had an i-touch for 3 years and over Easter Michael helped me download an app and set it up so I can use 'Facetime' a free Apple tool like Skype. The magical part is the receiving Apple device does not even have to be turned on, it will still sound an alarm to let you know someone is trying to reach you. So live video from the boat! Also sorted another App and made my little i-touch into a kindle! Brilliant! Now reading 'Boat, People and Me' on it) Over the weekend Michael loaned a whizzy video camera for the trip. It is a tiny hand held device and waterproof to 3 metres. I have found a clamp on mount for it too! See pic left, should be able to set it up to record whilst we sail! Just bought a new memory card, (using our EBay page!) 64 GB, enough for 60 plus hours of filming! Good grief I will be able to bore the family with that! Oh its warmed up outside, just minus 9! (wind chill) John

|

||

Speedseal Life now fitted! Beta spares showing the long hose, I am now just using the ends of this with copper replacing the middle section near the fan belt! Bolt sheered off in exchanger... It is just visible, right in the centre The other end with centre hole clear

|

Monday 8th April 2013. We have had the first days of real sunshine and I have been working on the boat! About time! Spent a few hours on board Saturday refitting fridge batteries, all fully charged and reading 13.7 volts on the Nasa meter. I fitted the Speed Seal life cover and a new impeller, the old one was OK but tossed into the bottom of the spares box. I have got 2 more new ones and 3 old ones that can be pressed into service, as well as the new Johnson replacement pump and spare impellor.. belts braces and lot of string! I found the old fan belt had rubbed the water hose, but whilst wondering how easy it would be to fit a bit of copper pipe instead I recalled that the motor came with a copper pipe and the replacement hose later fitted was only in one bit to save a pair of clips... I searched my store cupboard and there it was! So I removed the rubber pipe and cut the ends to suit the copper pipe, 2 new clips and problem solved! I have ordered another rubber pipe though, so I have 2 new spares. Also added a spare anode and other small parts. Whilst removing and checking the pipe stack in the head exchanger I had a disaster though, a bolt had sheared! See left... Had I not removed it to check would not have known till it fell off! Tube stack as it happened was as clean as new, as you can see from the pics, and the anode untouched. Shows how little use the motor had last year.... I had to bring it home and drill out the broken part and re-tap! Have just ordered new bolts, plus a few other bits as spares from Beta. Will refit next week with new 'O' rings and bolts, well greased!

|

||

All plastic can crusher Double hook safety line for £27.00! Lifejacket spray hood for less than £10.00 |

I have taken delivery of a few more bits,

using our EBay page. I found a very solid all plastic can crusher!

This will cure the problem of the rubbish bags filling with empty cans! Great to store on the boat, unlike the steel ones normally sold, will not go rusty! Also found a safety harness line half price to fit to another of the lifejackets we have aboard, so all the 4 main ones have harnesses, lights and now, spray hoods! I found a firm selling Crewsaver hoods for £9.90 inc postage, that's less than half price... why, well Crewsaver miss-printed the pouches the hoods are packed in, with the word 'Junior'! I have tried one on and they fit! Keith, if you are reading this another one is on it's way to you for your jacket! Go to:- http://www.wetsuitoutlet.co.uk/index.php and look for Crewsaver then hoods. |

||

Cables for extra services battery, just sample shot, a lot longer than this! |

The list of kit I am finding seems never

ending, if nothing else we are going to be well geared up! Measured up for the extra battery leads, then phoned my local auto electrical shop. after I got off the floor I went on line and searched, again using our search page on EBay. 2 cables, one 79 inches, one 29 inches are winging their way to me, with the correct 10mm ends. £20.00! I cleared one blade of the prop yesterday, the prop has a deposit of mud on it, it scrapes off easily to leave it shiny underneath, so when I have done all three blades the polisher will come out to get that mirror finish back, go faster prop! I am working on the boat with Phil tomorrow, have to mark up and drill the mast steps, too cold to finally fit, but once in place dry should be easy enough to add the pad of epoxy and work the rivet gun!

With any luck we will also be able to wash of the cabin top (remove the owl pellets!), and give the handrails a quick coat of 'varnish', Sikkens! Off to collect kit for working on the boat tomorrow. Oh and of course its going to rain! John |

||

|

Wednesday 10th April 2013.

Spent a very productive day with Phil on the boat yesterday, we managed to measure mark and dry fit all the mast steps! I will wait till the weekend and the warmer temperatures to mix the epoxy up to pad them onto the mast. Rivets and gun all ready to go. In addition we cleaned of the dust and crud, and the owl pellets! Rubbed down all the handrails, toe rail, bowsprit and gun whales etc and touched up any bare patches. (where I rub the big teak post as I come in, if I get it wrong!) Also cleaned off the remaining 2 blades on the prop, so that just has to be polished now! 15 days to launch!!! John |

|||

Sikkens for woodwork

|

Friday 12th April 2013. For the 4th consecutive day the temperature has been up and boat work has been possible, spent several hours with the varnish (Sikkens) brush this afternoon, all the handrails and half the toe rails and gunwhale done. Boat looks ready, nearly! The cream hull is gleaming and all we did was wipe it down with white spirit to get any dirt off, oil etc. The green is going to have to be 'T-Cut' though, before it gets the polish! I intend finishing all the Sikkens tomorrow and if the spares for the motor arrive get that all sorted too. Sunday the temperature will be up even more, so the mast steps can be epoxied in place. Sadly it is also pouring with rain, but that should not effect the Sikkens. Antifouling and hull polishing next John

|

||

CO alarm Sikkens for woodwork |

Sunday 14th April Bought another bit of kit for the boat yesterday, a CO alarm. I was actually buying one for the family as theirs had expired and thought, 'got one at home, why not on the boat too?' So I did. Is it worth risking it for £14.00? Spent all afternoon yesterday finishing off, almost, the varnishing, (Sikkens). I use the Teak colour... I just have the bowsprit to do and maybe some repair work on the toe rails at the bow. Reason? A southerly gale got up and blew rain, or rather spray from the gutters, onto the boat! I did manage to polish 1/6th of the prop though, (one side of one blade!) before the drills ran out of charge. Re charged and ready to go today. So I retreated and finished off an on going job, updating the charts.!! All done!! Still blowing today, but as yet no rain, so off to finish the varnish and hopefully fit the mast steps.... it is warm enough for the epoxy! Must get on, John |

||

|

hull polished! Marclear 'Workboat Red' antifouling. Beta marine 17 inboard. Lifejacket hoods fitted to 4 main jackets aboard. Belfield tide tables on CD.. Has glitch.. ports are not in order!

Water filter |

Friday 19th April. Just 5 full days before launch, panic setting in! Have loads of jobs to do. However Phil turned out to help last Tuesday and as a result the hull topsides are all polished and gleaming, (we had to T-Cut the green where is had chalked slightly) The final coat of Mer wax polish went on and it was a transformation, again. There was even time to mask up the waterline, taking the antifouling up just half an inch.... to allow for all that extra kit! Then we got a coat all over and 3 coats round the waterline. I will be back later to add a second coat of Marclear to the rest. After the tape was removed we stood back and admired the job! Nothing like a clean, one colour bottom and bright shiny paintwork! This is her 23rd year and she still looks like a 2 year old! We also looked at the mast steps I had riveted on and filleted with epoxy. Only one did not work properly because a little of the epoxy fouled the mechanism, but in trying to clear it a lump fell out so I have to re epoxy just one fitting, the rest are fine. I will fit some foam pads to each step as otherwise I suspect they may rattle slightly, which could prove annoying! When I got home Tuesday, the Beta Marine parts had arrived, so this weekend I will be servicing the motor, running the engine up ashore and changing oils. I intend varnishing washboards and the crew back rests we use in the cockpit on the guard rails too. Then all paint and varnish will have a few days to harden. Through the post arrived the last pair of lifejacket hoods, Keith has got the one I sent him and it is fitted to his jacket already! I visited the chandlery down in Maldon, Marinestore, bought the Tides CD and a filter for the water system, plus new Aqua Tabs for the tanks.... I had to order that last Chart, the Imray C28 as it is so new they had not got a copy, I also ordered 4 Tidal atlas's I needed and had been unable to buy cheaply, Marine scenes prices are better than almost everyone for these! I will take a run over to Burnham's branch of Marinestore.co.uk Sunday, if I get time, as they have a good selection of Musto clothing there and I am interested in a thin thermal layer to wear under sweats etc. Talking of Sweat shirts.. I took delivery of a box full of crew clobber yesterday, new polo shirts, long sleeved rugby shirts and sweats, got to keep the crew warm, and smart! That's all for now off to do the antifouling and epoxy work! John P.S. just back from boat, freezing down there, too cold to paint or epoxy, so brought a few bits home to varnish... Where did spring go? |

||

|

Note prop covered with plastic bag! Do not want paint on my shiny prop. I coat it in lanolin to protect it...

Morris Minor tow truck? No just showing off the paint! |

Monday 22nd April 2013 Fast running out of time, but over the weekend have managed to get a few jobs sorted. For starters it was warm enough to finish the antifouling! Also re epoxy one mast step fitting. Managed to get the start and auxiliary batteries fitted too. Sunday saw me putting the engine heat exchanger back together, with new seals and bolts and refilling with antifreeze. Got a slight weep from the back end, where of course it is the most difficult to check. I gentle tweak of the spanners and I stopped it, did not want to over tighten and break a bolt again! I managed to replace the primary fuel filter without lifting the cockpit floor, which saved breaking the watertight seal, fiddly but possible. However I now have to find one of those long flexible wands with a magnet on the end to retrieve the spanner I lost in the bilge, under the motor. It has to come out!. I bled the fuel system, easy now with the new fuel pump with manual primer. I rigged a 5 gallon jerry can on the stern, it has a water pipe fitting in the bottom and a hole cut in the side, hanging from the ladder on the stern it catches water from the exhaust and recycles it to the inlet fitting on the underside of the boat. Once filled with about 4 gallons of water I fired up the motor. After the motor had self bled the last drops of air, (it stops of course when air is found...), I managed to keep it running at 1500 revs for 20 minutes, so pretty sure it will be reliable when we are dropped in on Thursday and long enough to warm up the oils and check there were no further leaks. I then changed the engine oil and filter, then the worst job, crawling down the quarter berth head first with a long pipe, sucking the gearbox oil out, pipe full by pipe full, to change it. Came home with taste of ATF... but it was a good job well done. Went to Marina for dinner to celebrate and whilst there fitted the mooring ropes to our pontoon! Another job ticked off the list! Monday I spent another 3 hours on board, I cleaned of any excess epoxy from the mast steps and polished the ali spars. As it was getting dark I retreated inside and fitted the extra auxiliary battery and wiring and altered the monitor to read the now 200 Amp battery bank. I could then refit all the panels on the engine box. Looks a little tidier down below now. Tuesday I intend to finish polishing the prop, nearly mirror finish! Then fit all the halyards to the spars and lash all down for transport. With any luck Wednesday I will just have to tidy up. I cleaned off all the fenders over the weekend and also varnished the washboards and back supports we have on the guard rails. Gave them another coat today. The gear is starting to surface from winter store, all clean and washed at the end of last year, and stored in the dry, so all good. There will be 3 moggy van loads to go aboard! 2 days till launch! John |

||

|

If you look carefully you may just make out resident Little Owl! Out into the daylight, now we see the bits I missed! The short tow to the water In the slings, antifoul touched up..

keel wet again, for another year |

Thursday April 25th.

Should be doing today's in Red! We are afloat! Keith, Phil and myself were at the barn this morning by 10 and made her ready for the road, Phil swept up the barn and Keith and I attended to the trailer and lights, then a short trip down the lanes to Bradwell. Sadly the crane was out of action at Bradwell, so we set too to raise the mast with our normal gear. We had barely lifted it off the deck when the A frame bent, quickly lowered back and it was apparent we were not going to use it again without strengthening it, we dismantled it and plan B came into effect. The marina has a Bobcat fork lift, with legs and extending boom, we used that. Soon mast was up and tweaked to get upright and in the centre of the boat, lowers were tightened to keep the sail track straight and after a bit of a struggle, the back stays, which seemed to have shrunk over winter, were reconnected and the pre-bend I like to see put into the mast. The new mast steps got their first trial, as Ian's rope strop to hoist the mast got caught under the spreaders on one of the shroud clevis pins! You could not make that happen if you tried all day! So the rigging was all tightened to make the mast safe and Ian was up in a jiffy with the new steps and un-latched it! A quick sandwich break and then the marina lads were there to lift her off the trailer so I could get at the bits the antifouling roller had missed. (because the trailer get in the way). By 1500 she was back in her element and back on her berth! The crew stayed and assisted, so all the rigging could be double checked and tightened and the sails bent onto the mast and forestay. We fitted the new sail cover, the old one had done sterling job and had lasted 22 years. The new one had winch pockets and a little more room for the sail, a better fit! Keith even scrubbed the resident owl's poo off the stern deck! By 1800 all was ship shape all the tangles of running rigging sorted and all snugged down. I even got the solar panel on and in the evening sun could see it working. I will be back to her tomorrow to do a clean up down below and start adding gear. At the moment the antifouling is showing all round by at least 2 inches! By the time the rest of the kit comes aboard that will be down to half an inch! Good job done, now the fun begins! John

|

||

coastal pack to top up flares box.

Water filter fitted. |

Thursday 2nd May

Just over 2 weeks till we set off and loads to do! We were down on board Tuesday, first chance we had got to get aboard as we have been rather busy moving house for one of the family, bad timing! We managed to clean and disinfect with Dettol wipes, throughout, including the insides of lockers etc. Then polish up the varnished bits with polish wipes, make a fair job of the clean up. bilges dried, (from the antifreeze mix drained from the motor), and all made tidy. Even managed to get the dodgers on, but by then the cold easterly was not something you wanted to be out in. We retreated to the bar. Wednesday I had planned to pick up the old dodgers that were being modified into fender and topsides protectors and a small extra dodger for the middle of the stern. Sadly the clutch control rod broke on my Morris Van and though I could limp home with out a clutch I baulked at driving to Burnham, instead I broke out the even older BSA Bantam for it's first run this year. By the time I got back with the dodgers I was frozen, a nasty Easterly... So I resorted to going through the flare box and ordering new! I also looked at the first Aid boxes again, loads of stuff woefully out of date, well the dates on the sealed packs had expired if that is anything to go by... to be honest a clean wrapped gauze bandage with an old date would be better than an old handkerchief! but I have found I can replace all at Tesco pharmacy, so in the next few days, I will be doing a canned food etc. shop and will add these bandages to the list. Add also anti midge cream, insect bite and aspirin and all the other pills and potions we normally carry. I also took the opportunity to scrub all the carpets. Yes we have carpet. Remember 'Flotex'.? The kitchen carpet you could spill food on and wipe up. Brilliant on the cabin sole. Even better as it was free! The off cuts from my sisters kitchen 20 odd years ago! The new flare pack arrives Friday as does the new rod for my Van's clutch! So Friday afternoon I hope to be on board and have all the rigging wired, taped up and secure. the curtains came down Tuesday, are washed and will go back up too, along with the new bit of dodger. I have one tiny bit of woodwork to clean up and varnish, where I removed the keel bolt and slightly damaged one of the poles supporting my cabin top, a bit of sanding and a lick of varnish will sort that. Then I start loading gear, and plugging in the electronics etc. I fitted the new water filter Tuesday and will be filling tanks etc next. (bought a supply of 'Aqua Tabs' to sterilise the tanks enroute too.) Hope it is warmer down there tomorrow! John |

||

|

Saturday 4th May 2013 Spent 4 hours yesterday afternoon/evening sorting the boat, having first fixed the van's clutch rod! For the first time this year the sun was really warm and that dreaded Easterly had dropped. Managed to mouse every shackle on deck and in the rig and tape all rigging screws and small reefing line blocks. These days I use small electrical ties to secure the pins in shackles, green ones of course! All the safety lines on the guard rails checked and the new stern dodger fitted. Carpets fitted, then I remembered I had to do the deck support pole, so lifted a couple of floor boards in the cabin and sanded and varnished the damaged area at the base. Will give that another coat today. Off to clean and polish the cabin top and load another 3 boxes of gear later today, will fill the water tanks too, at the moment the boat has a distinct list to starboard, as there is no gear or water or food on board the other side! Got the VHF and the GPS up and running. Spoke to Digital Yacht and discovered I can split the AIS output from the ANT200 to both plotters, clever! (Subsequently discovered this not the case, can only supply one or the other!). Have just ordered 6 small brass cranked bolts to secure the washboard, using the EBay page of course. At the moment it is raining gently, but hopefully that will have stopped before I get back down there. Busy weekend at the marina, not only are all the owners down for the holiday weekend, there is also a Triathlon, with a creek swim Sunday. We will have a putter out later in the week to test all the kit, when all have gone home! Off to load the boxes with more gear to take down! john

|

|||

|

John's SOS logo. Mail and spares service handed over to British Seagull, just whilst I am away. Silk sleeping bag liners, by 2 get 1 free! Navionics whole of UK plus Ireland and continent. the last chart purchased, from Maldon's 'Marine store' cheaper than anywhere else! have a pair of these surplus to requirements now, suit 30ft or larger boat, so you can fit them in! |

Wednesday 8th May 2013. Closed my Seagull business down today, for 3 months or so, just tying up the loose ends now. British Seagull are looking after it from now. We were down the boat over the Bank Holiday and loaded up with tin cans etc, loads of food. Put her down in the water a bit, what with that and filling the water tanks! Still got over an inch of antifouling showing and all I have to load on board now is my clothing and bedding. Crew Keith has acquired me a new warm sleeping bag and I have taken delivery of the silk linings! Idea from trekking daughter. We fitted and initialised the new Lowrance Plotter, very clever bit of kit, all self contained and mounted atop the cabin top is visible easily anywhere in the cockpit. The 'Navionics' card gives all of UK charts. Talking of charts, picked up the last chart yesterday, Imray C28, that we will need on day 2! Also picked up 4 more tidal atlases for Scotland and Ireland down to the Scillies. So that is a full house on charts and Atlas's. They will be packed in sealed plastic bags on board till wanted. Also bought a new white hand held flare as the one in the companionway is just out of date. Whilst on board I filled the Panic bag. Waterproof camera, EPIRB, hand held VHF, set of coastal flares, 3 survival suits, 4 bottles of water and two big bars of chocolate. I have a large box of just out of date flares as well, just in case. There are also three sets of mini flares, small enough to carry in an oilskin pocket and another EPIRB that will live in my pocket or strapped to my lifejacket. We loaded a half hundred weight of dry cell batteries on board too! The only major item I have not put on board yet is the dinghy, will wait till the tide is up to carry that aboard. It will live on deck part inflated... I have reached the decision that I cannot carry the 2 fold up bikes though, there is just not room. They are too bulky for stowing below, not that there is any room! And likewise bulky and weighty for deck storage. was a good idea. Anyone want 2, near new, clever fold up bikes with all mod cons, lights, carriers, suspension etc, in bags? I am trying to sort all the domestic matters now in preparation, you have to think of all sorts of things, paying car insurance, and making sure there are no letters or mails outstanding. Just paid for my SOS domain names! Last few SOS orders coming in to be sorted too. The EOG enrolment form will be dealt with by John Stevens and Chris in the Netherlands, but have no one to send out CD's and deal with general enquiries as yet. May divert some mail but may have to simply add an auto response. Peter the webmaster and I will be talking about this with John and Chris this next week. John.

|

||

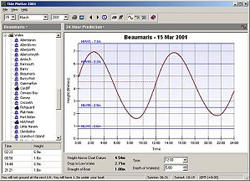

Belfield Tide plotter graph. hidden harbours, interesting but most of no use to us! Hefty tome full of good info and chartlets!

Another excellent pilot, lots of info and chartlets. |

Friday 10th May. Just off down to the boat, odd not to have to reply to 40 mails before lunch! The SOS switch over seems to have worked, or at least I am not getting the mails and calls. I contacted Keith Belfield of Belfield Tide Plotters today, I had as usual bought one of his UK tides CD's. I found the ports could not be viewed geographically, and were only listed in alphabetical order, not good. Keith showed me how you could click the chart symbol on the menu tab and get a graphical representation of where you are, with this you then can simply move to the next nearest place that tides have been calculated for. Also shows the tidal streams, now that is clever. Van loaded with dinghy and bedding to find a home for on board. Out of interest I also loaded one bike in it's bag, just to see where it may be stowed....? John P.S. Just back from boat, I have definitely given up on the bikes idea, they would be just too much clutter on deck and there is no where else to put them... Fitted the Logo to the sides of the cabin, courtesy of www.names4boats.com Took down a few more charts and pilot books, have to put them into plastic bags and stow them away below the bunks next. When I returned home the postie had delivered several more pilot books, more bedtime reading, just one to come. John |

||

|

Tuesday 14th May 2013. Just a few days to go now and I am tidying up the loose ends. Spent an hour on board yesterday searching for a set of waterproof pens we had mislaid. found them. Amazing how items get stowed away into corners. Whilst we were on board I gathered up my oilies and brought them off, washed them overnight and re-proofed them, along with a couple of light weight jackets. Had forgotten to do this earlier! The last pilot books and some more telephone contact numbers loaded into bag ready to go aboard. We have to split the charts into areas and include with each chart any contact numbers etc, then seal them in plastic bags and stow out of the way till needed. Storage space aboard is now at a premium and it did not help when Darian found a few more jars and tins of food. They were literally 'shoehorned' into lockers! We have booked a table for 7pm at the Marina bar Saturday night. Most of the participants and their other halves etc are coming along, Daughter Jenny is working, cycle ride twixt Paris and London I think.... Some of the crew will be leaving gear aboard, though not sure where it will stow! (Bulky items like sleeping bags.. though to be honest the modern sleeping bags compress down to very small packs, so they should stow in the toe of the quarter berth OK. Took some pics of the new logo fitted to the boat, courtesy of Mel at www.names4boats.com I will post them once I find the camera lead, which I must have stowed on the boat! The weather forecast for Sunday has changed twice in the last few days, from F3 NW, perfect! To Gale 8 NE, no way, and now F4 Northerly, not good... we will have to see how many more times it changes. After the wind and rain for the next few days, hopefully it will settle down! Off to get my quarterly hair cut now! John Click here to go to the ship's log page ************************************************************************************

|

|||

|

The big plan for …. 2015? now 2016!!! and after medical problems, 2018!!!!!!! January 2014 and I have decided to update and continue this page, why, because I really want to finish the circumnavigation and I will be doing some modifications to 'Fiddler's green' as a result of our experiences, so will continue to log them.

|

|||

|

Liferaft in for service. The new cooker ordered.

New 105 Ahr fridge battery Hi duty Hello plug and plug with car sockets Laptop support with cooling fan. Laptop charge lead for 12v.

|